Dissipation factor of capacitors is a function of temperature and frequency (of supply voltage). In the other words, capacitors’ losses vary with temperature and frequency. Dissipation factor of capacitors has three additive components. The first and second components are related to changing of capacitors’ parallel and series (ESR) resistances due to temperature. Since both of these resistances increase with temperature, so these two components always are positive. The third component is related to intrinsic characteristic of dielectric material. Dielectric dissipation factor may increase, decrease or even remain constant with increasing temperature. So, cleverly choosing of film capacitors may decrease the probability of capacitor overheating and extends its overall life.

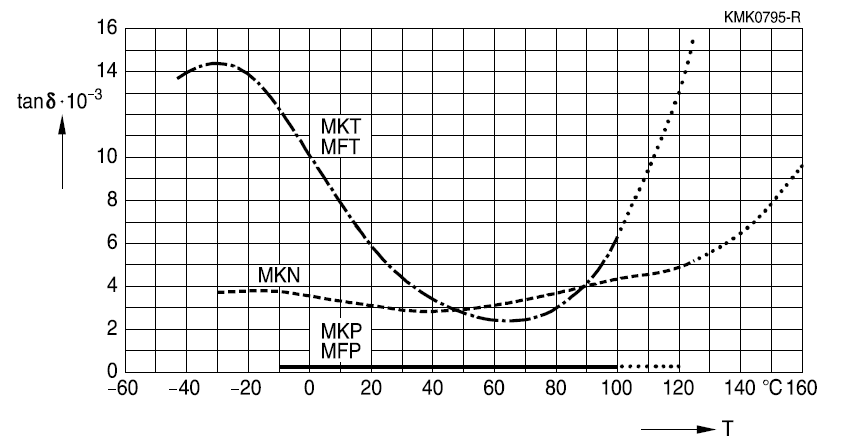

In below figure, dissipation factor-temperature characteristics of the metalized film of polyester (MKT & MFT), Polypropylene (MKP & MFP) and polyethylene naphthalate (MKN) is shown. As can be seen, the best choose (from dissipation factor-temperature characteristics view point) is polypropylene film capacitors (because has the minimum dissipation factor over a large span of temperature).

Fig 1. Dissipation factor-temperature characteristics of metalized film of polyester (MKT & MFT), Polypropylene (MKP&MFP) and polyethylene naphthalate (MKN) in 10^-3 resolution of y axis

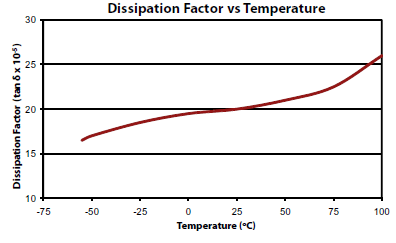

Of course, it must be mentioned that by increasing the resolution of the above graph (changing vertical axis from 10^-3 order to 10^-5), we can see that also in polypropylene film capacitors, dissipation factor (Tangent of delta) will increase vs temperature.

Fig 2. Dissipation factor-temperature characteristics of metalized film of polypropylene (MKP&MFP) in 10^-5 resolution of vertical axis